Discover On-Demand Manufacturing

Maybe you've heard of on-demand manufacturing- the process by which goods are produced on a small scale to exactly meet demand as soon as an online order is placed- but you're curious about how on-demand manufacturing will affect your supply chain, the environment, and your bottom line. There are countless benefits to on-demand manufacturing, no matter if your main motivation involves cutting costs, transitioning your brand to follow more sustainable practices, or creating a scalable company.

Perhaps the most obvious benefit of adopting an on-demand model is the end of inventory. Typically, brands will design an item and send it for production for several hundred (or even several thousand) units. The units are shipped to a warehouse, they are shipped out as a customer or store purchases one or more products. The brand must predict how many units will sell, and will end up with extra products if they do not sell as planned. Then, brands are stuck with garments that are out of season, and must cut their losses by selling on sale. Alternately, a brand could underestimate the popularity of a garment, which means they miss the opportunity to sell more products as it is too late to wait for a factory to create more.

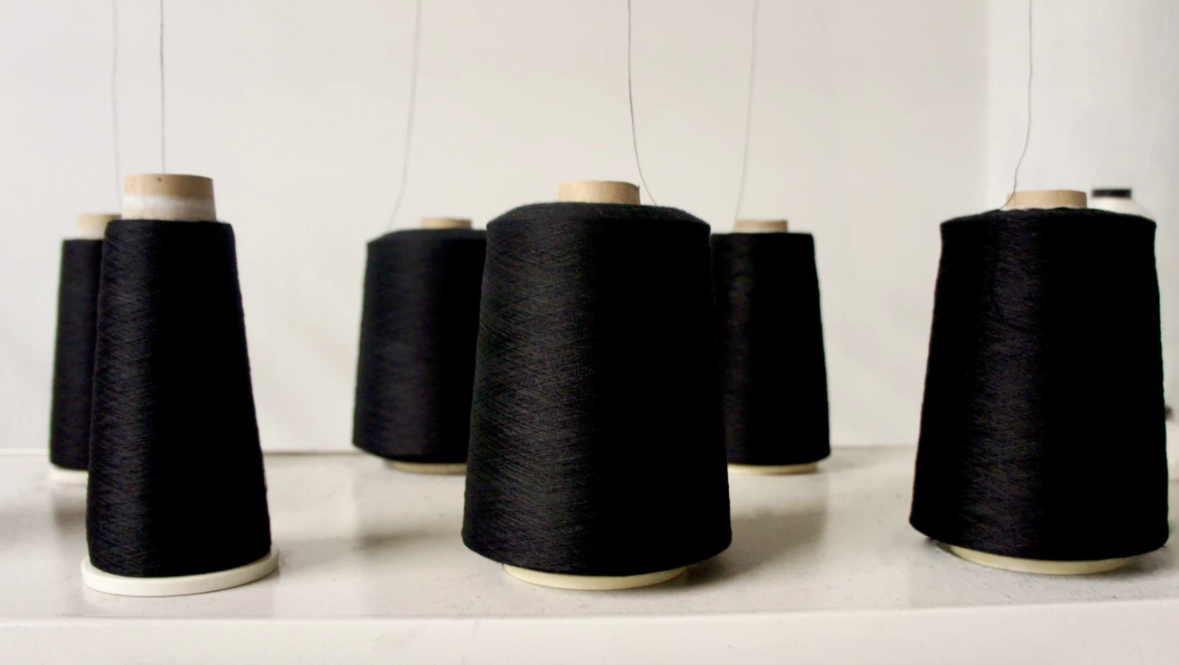

With the on-demand model, customers order products online, then the details are sent to the on-demand factory. The factory produces the exact amount of garments necessary for the customer (technology such as 3D knitting machines makes such rapid small-scale production possible) and sends it right away. This way, no inventory is wasted, as garments are produced when there is a real need for them.

Another benefit of the on-demand model is the unprecedented speed at which styles hit the market. In the conventional model, brands design clothes that hit the shelves up to a year later. Prototyping and production take so much time, that brands must carefully forecast fashions far in advance. Using an on-demand model, a style could be ready for sale in as little as 3 weeks; 1-off prototypes are produced quickly so that brands can make adjustments, then the on-demand factory is ready to start production immediately. The on-demand model can streamline the production process and ensure your brand stocks the latest styles. Additionally, mass production may leave you with questions about where your garments are made and who is making them. On-demand production involves a personal relationship between a brand and a factory, so your brand can be confident you know where your clothes are made.

Finally, on-demand ensures each of your garments is produced with the highest quality. When garments are mass-produced, attention to detail is lost as factories try to hit strict deadlines. The on-demand model inherently involves a high level of care for each garment because producers can focus their full attention on the specific piece at hand. We know you and your customers will be able to tell the difference.

There are endless financial, ethical, and logistical reasons why on-demand may be right for your brand. Contact us to find out more and get the conversation going.